Shell Accuport

Tasks

AI Design, Data, Research, Beta Product launch

Time

Aug 2018 – March 2020

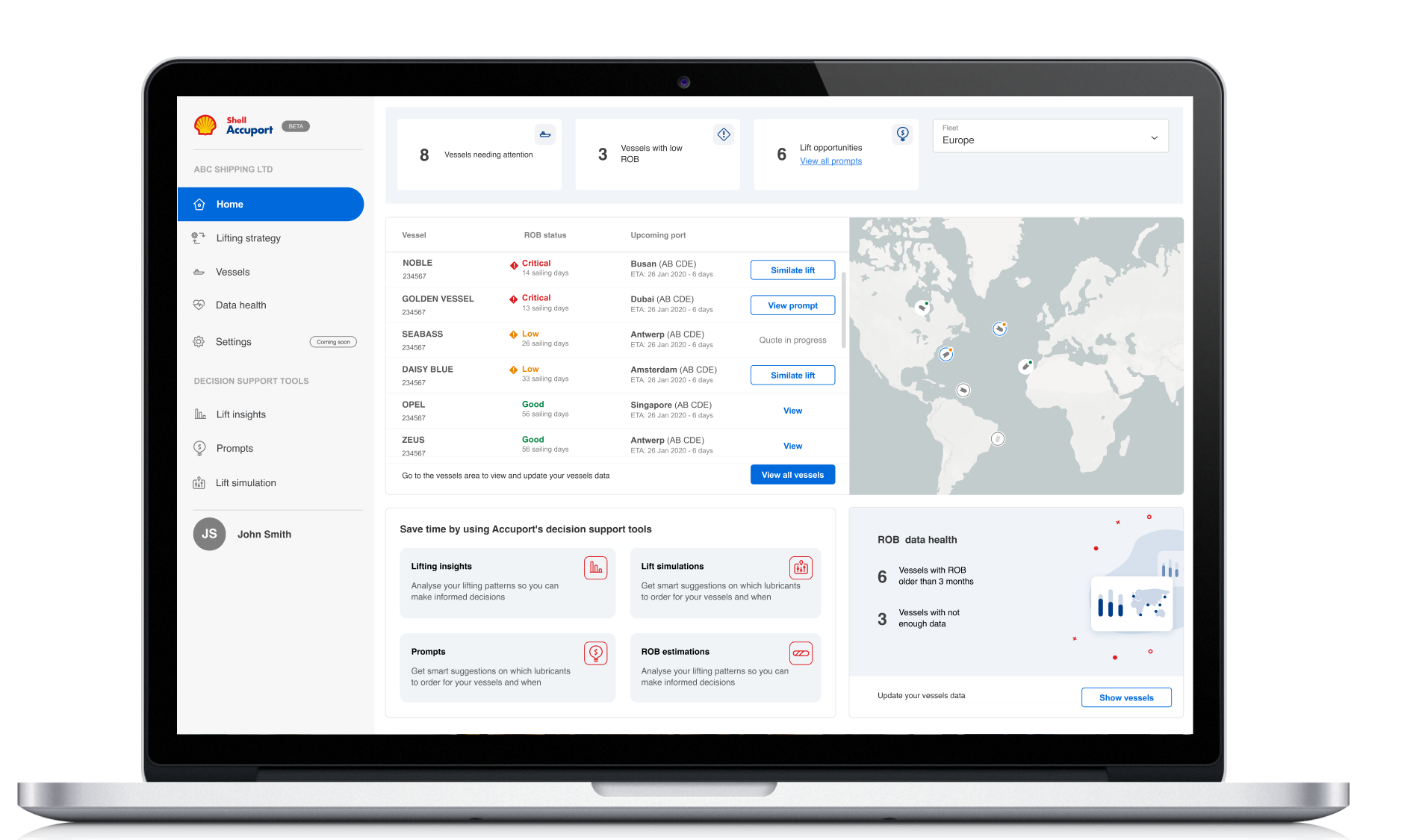

Accuport is a digital platform helps shipping companies efficiently manage lubricants demand and optimise fleet performance for lubricants purchasing and consumption using AI.

Accuport began as an email prompting system powered by AI, where shipping companies received an email reminder that included products to place and order in time when a vessel was approaching a good port. This proved to be well received by customers, but they wanted the ability to customise order prompts, as well as a holistic overview of the vessels.

Vessels engine lubricants are replenished infrequently in a year. This can often result in last minute and emergency orders, resulting in an expensive purchase and stressful experience. Some vessel types do not have a fixed voyage schedule, it is unpredictable due to trading markets. This makes it difficult to plan lubricant lifts, and making a stop outside of the commercial schedule costs the shipping companies a lot of money.

Users found the email promps useful but the process was still reactive.

Challenge

Business opportunity

Provide visibility

Provide simulated data using AI of stock levels on board. Giving users a holistic view of vessel needs.

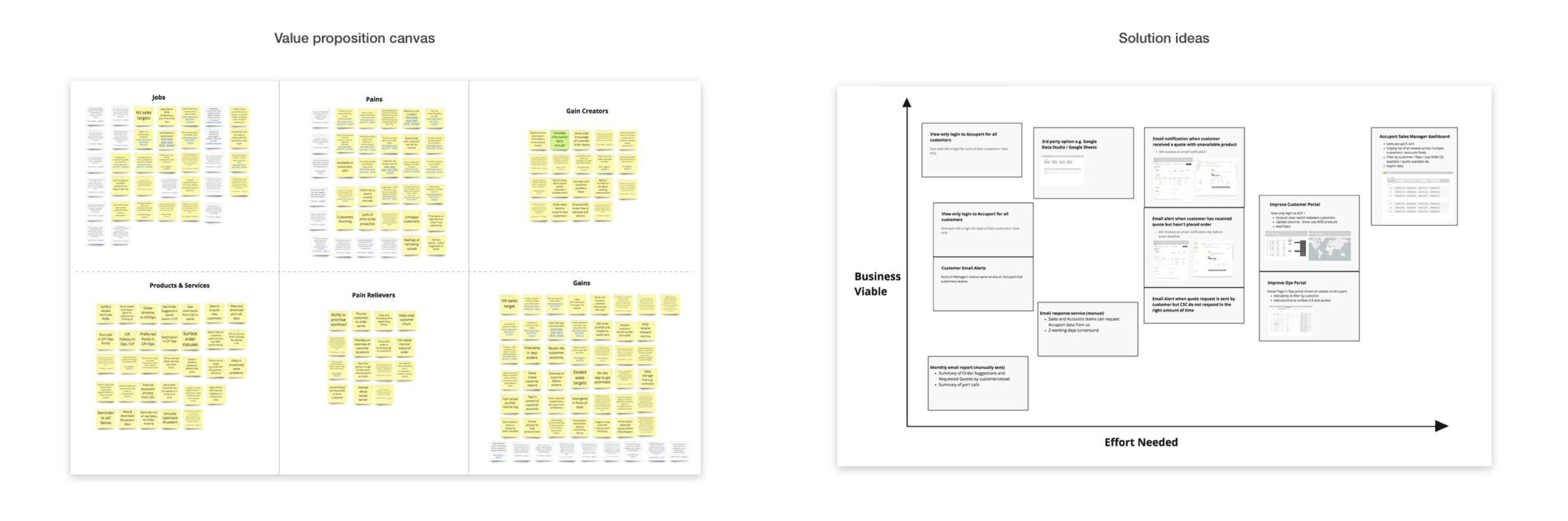

Provide promps for customers to ensure that orders are made on time, and to avoid customers going to competitors. Give users an interface to have a holistic view of reserve stocks on vessels. This would give them the ability to be proactive, and forecast future purchaces, rather than reacting to stock in need of replenishing.

This collection of data Shell to be able to fulfil orders efficiently and to use data to better forecast stock at ports, which ensures enough stock is available at busy ports and reduces waste at less busy ports.

Our strategy

AI Predictions

Tools to help users forecast and plan purchases, especially for vessels with unpredictable schedules.

Insights and feedback

Using data to understand purchasing patterns and provide insights to be more efficient.

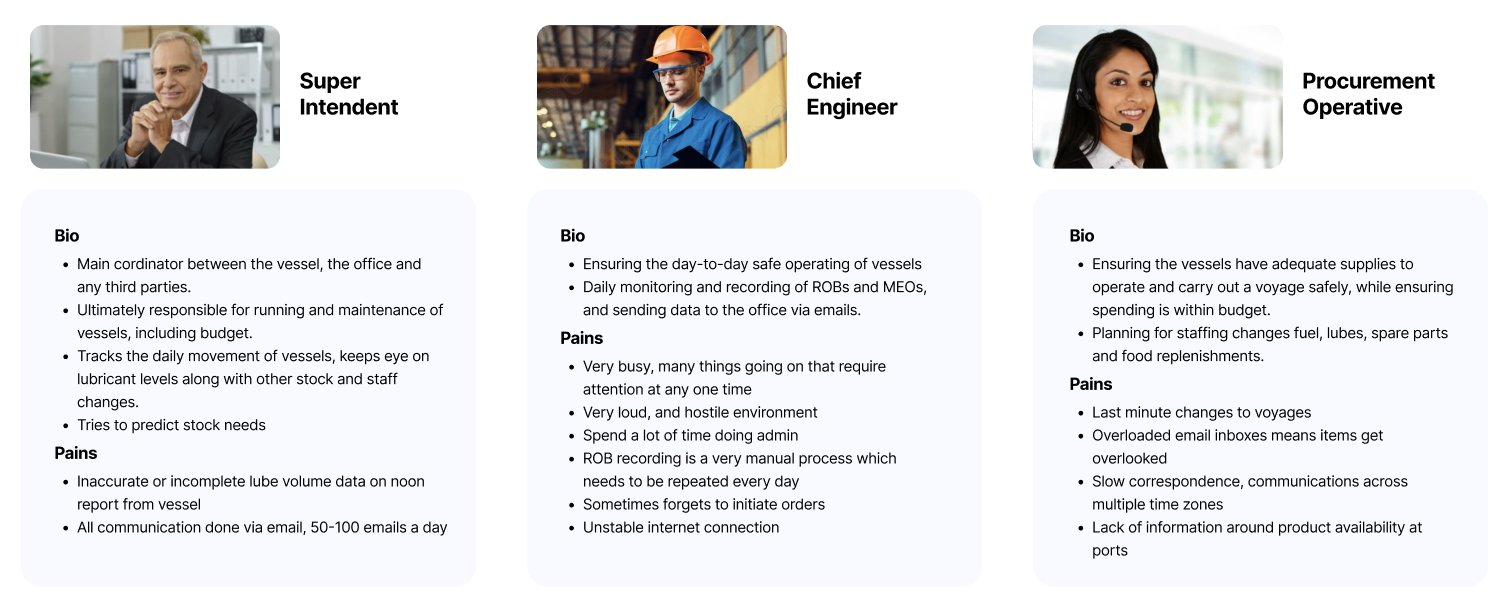

Our users

The procurement process

I conducted research to understand current procurement workflows, how the AI order prompt solved pains, and areas where we could improve our product.

The main issue is a lack of visibility of stock for both Shell and clients. This causes a lot of delays within the process. Procurement operative relies on staff onboard ships to update them on stock reserves, and ask for orders, resulting in reactive workflows.

There is also no live data of oil stock at ports, orders have to be checked manually before being accepted for clients to know if their order will be fulfilled.

Ideation Workshops

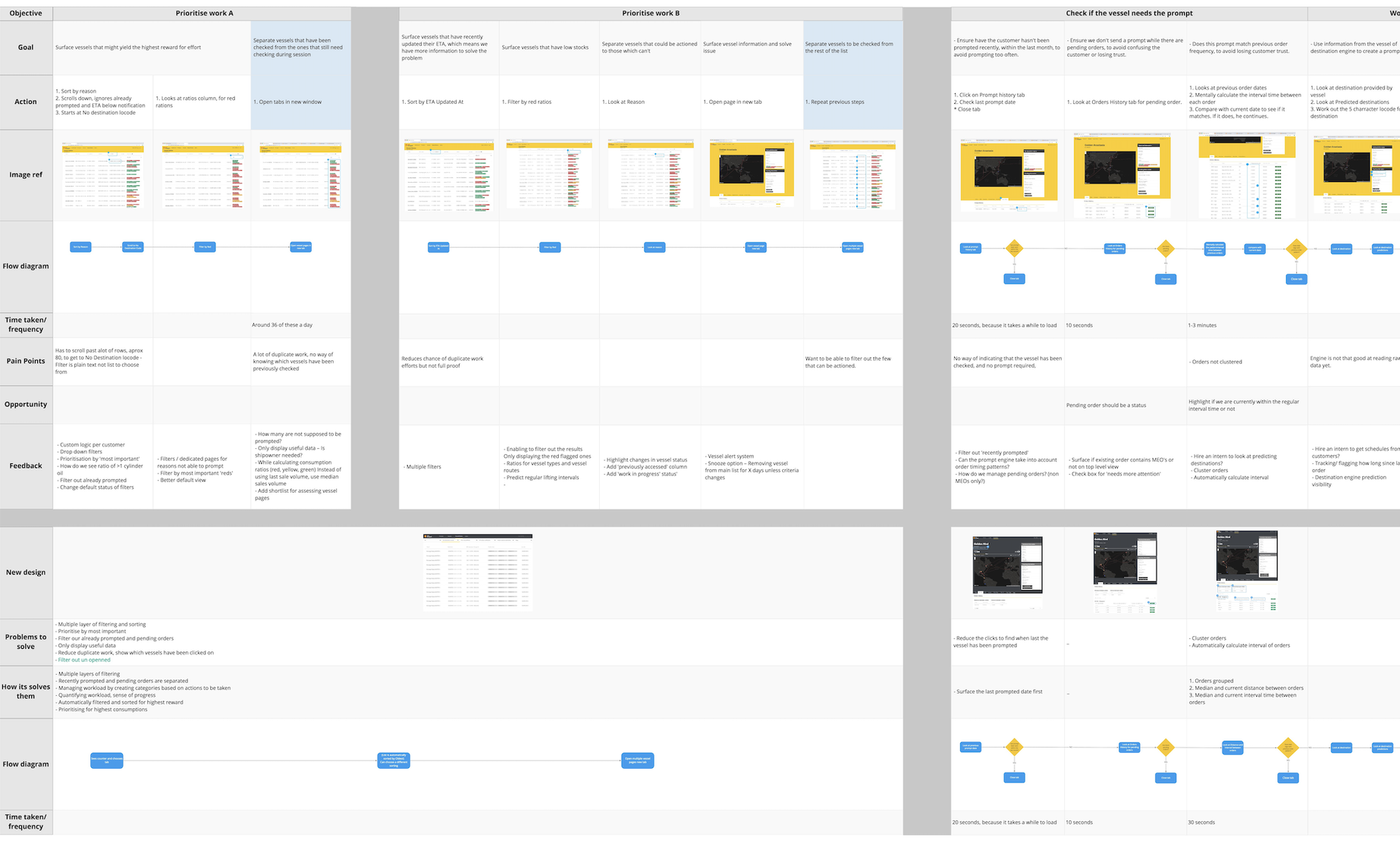

AI Order Suggestions

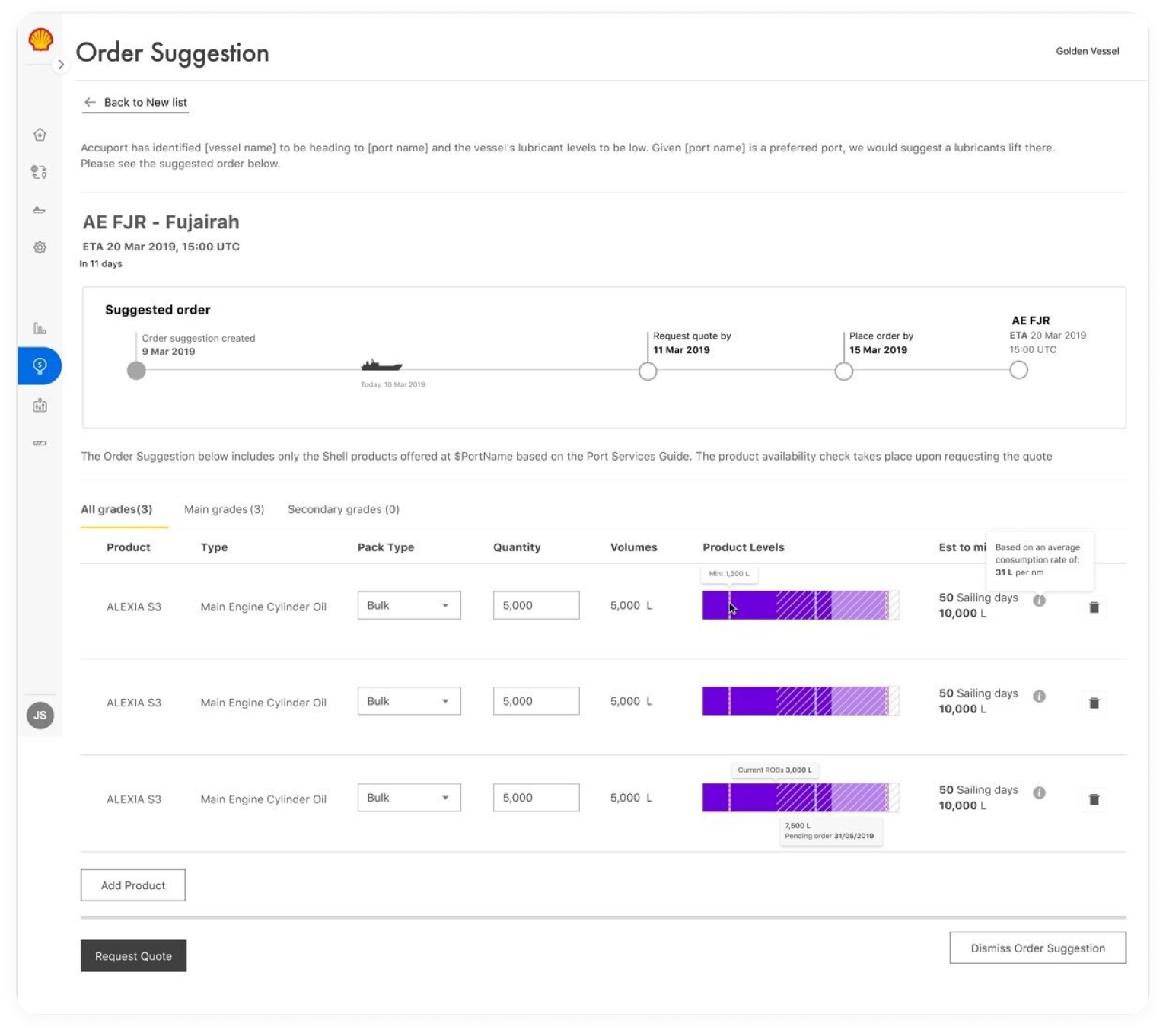

A vessel receives an automate Order Suggestion when there is oil that has low stock and is approaching a good port to lift. This was calculated based on previous purchase volumes, nautical miles travelled, and type of oil.

The goal of the ML engines is to answer:

When to generate a prompt

For what port – preferred only

What products to include

What quantities

The user then able to review and edit the products and quantities, then submit an order quote. The user then uses their normal channels to place and confirm the order.

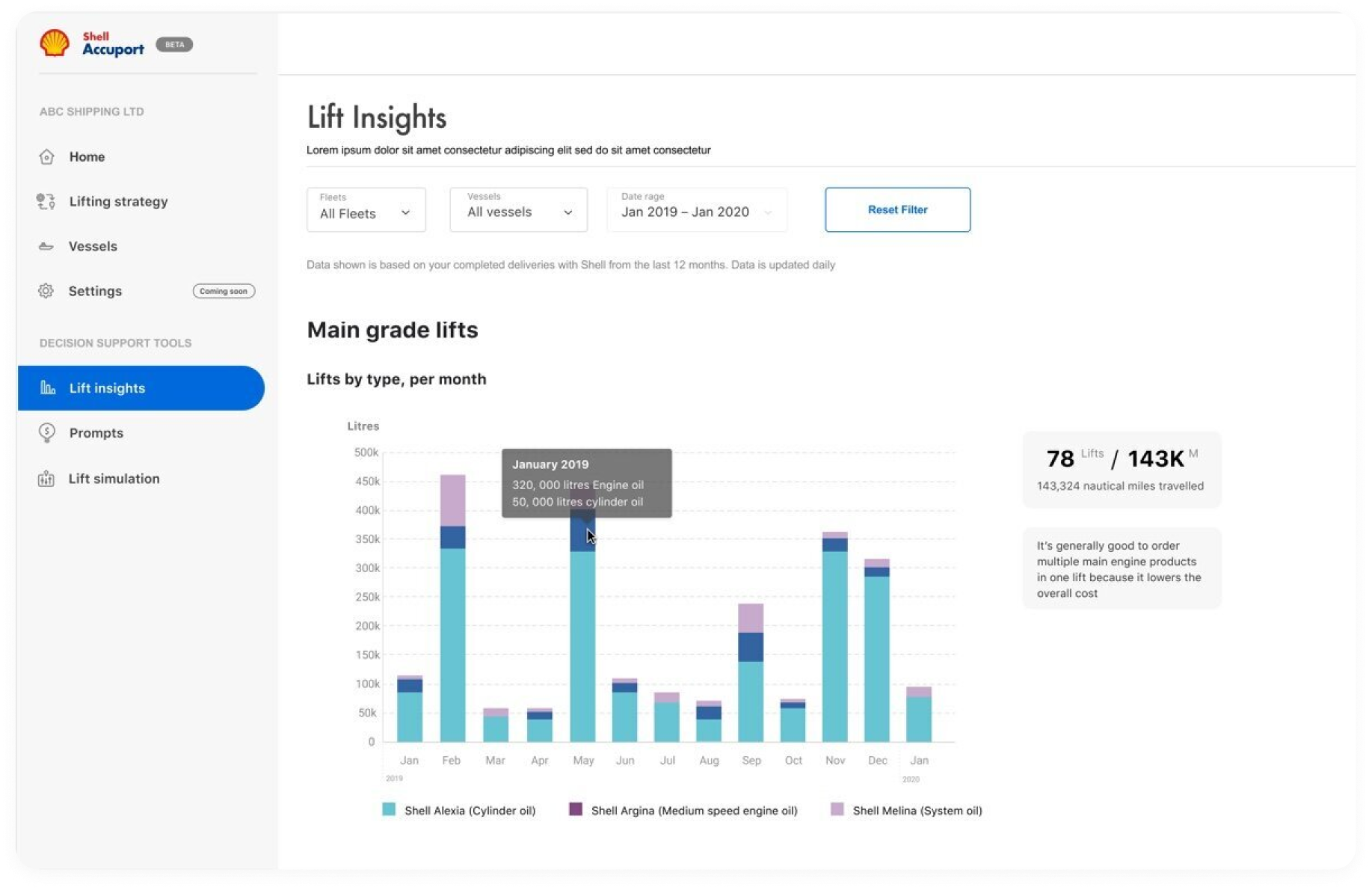

Lift insights

Using the data we have on previous orders, Lift Insights allows customers to understand their current lifting behaviour, and what affects it.

Insights on fleets historic behaviour helps customers to make informed lifting decisions in the future, and track them against performance benchmarks.

Using our research we highlighted data that users find most important when conducting analysis:

Type of products are ordered by the vessels, volumes and order frequency

Ports the vessels place orders – Preferred ports provide better value for money, and easier delivery services

When the vessels place rushed orders and how frequently – Rushed orders can have expensive delivery, and can highlight vessels that were in an emergency

Products frequently in rushed orders – This highlights products that are often forgotten in orders.

User testing

We worked with 5 shipping management companies who used the product within their procurement workflow during this co-creation process. We were able to gather data on how they used the product, and see the impact on their procurement process.

We conducted regular qualitative user tests with the customers, and often visited their offices. This allowed us to observe them using Accuport and get a deeper understanding of their working environment.

Outcome

By having access to this data, companies can work towards more efficient lifting behaviour:

More deliveries at a selection of agreed preferred ports

Minimise small and rushed orders

Minimise the overall number of deliveries

This was not just a result of surfacing data, but also transforming the company working processed for Procurement operatives to take the lead in ensuring vessels are well stocked, instead of reacting to order requirements from the vessels. This also resulted in elevating work load for workers on the vessels.